Leading Edge Erosion (LEE) is one of the most common and costly problems for all wind farm projects in general and in Vietnam in particular. So, what is leading edge erosion of wind turbine blades? What are solutions for leading edge erosion in Vietnam? What is leading edge protection? Why is leading edge protection such a major problem for wind turbine blades in Vietnam?

Profound understanding all above concerns, MB WIND POWER SERVICE JSC have sought and offered the optimal solutions for leading edge protection for wind farm operators throughout Vietnam and nearby region. We offer a full service package to inspect and prevent wind turbine blades from erosion in a safe, efficient, rapid and cost effective way.

What Is Leading Edge Erosion?

Leading edges erosion (LEE) is a phenomenon that material of wind turbine blades or propellers is removed from the blade surface due to being pelted at high speeds by rain, snow, hailstones or other particles in the air.

When the leading edges of a blade begin to be eroded, the blade’s surface can become rough and scratchy. Fiberglass or composite structure beneath can be delaminated by air, causing even more damage on account of degradation the aerodynamic performance and decay of the structural integrity of the blade, including:

-

- Up to 5% reduction in turbine performance per year.

- Repairing wind turbine blade erosion causing wasting much more money and time

- The turbine expectancy life will be significantly reduced if leading edge protection is not applied properly.

And this also demonstrates the special importance of leading edge protection for wind turbine blades in the overall process of construction and installation onshore and offshore wind farm projects. So, let MBWIND come up with the perfect solutions for leading edge protection in Vietnam with the most innovative and robust methods in current day.

Leading Edge Protection Solution for Wind Turbine Blades

According to the experimental testing campaigns that were performed during leading edge protection development, MBWIND recommend two advanced leading edge protection solutions that are protective tapes and coatings (or gelcoats) in overall operation and maintenance process.

Protective Coatings for Leading Edge Protection

Based on the results from the rain erosion testing, the coating materials which most suitable often contain high-strength and resistant material components, such as: polyurethane, epoxy, polyester. Protective layers are applied to the turbine blade surface in-mould or post-mould.

We prefer to use coating which are utmost adhesion properties, wide range of hardness, flexibility, abrasion and impact resistance, strong flex-fatigue and resistance to the impact of heat, chemicals, weather and physical issue. We consider not only the factors of waterproof, resistance to friction, as well as withstand pressure from weather agents such as rain, wind, hail, UV, but also the aesthetic requirements, even tone, shine and smoothness.

Protective Tapes for Leading Edge Protection

Besides coating, we also offer another method of leading edge protection for wind turbine blades, which is application protective tapes to the erosion wind surface. Reliable shells must be robust yet highly flexible, durable, and made from polymer materials such as polyurethane.

Because of the characteristics and structure, the method of applying protective tapes can avoid a number of defects encountered when coating including alligatoring, blistering, cracking, wrinkling, and others. Moreover, this remedial method is also less affected by the environment and weather conditions, so it is often prioritized for direct application for in-field repairs. In essential, we still make sure that the protective tapes used must meet the requirements such as durability, sturdy, heat resistance, waterproofing, lightning resistance, and moisture-resistant adhesive.

What We Can Do When Wind Turbine Blades Erosion Occurred?

Leading Edge Protective Coatings

With protective coatings, there are two methods that are coatings and gelcoats. Base on the surface condition, we probably apply a primer layer along with the filler and the coating to create an optimum adhesion between gelcoat layer and the composite laminate of blades. In general, we apply the protective coating leading edge following these steps:

-

- Clean the surface, remove dust, grease and other contaminants.

- Sand the blade surface

- Clean the surface with dust binding cloth.

- Apply coating, combine adhesion layer and hardener (if necessary)

- Complete gelcoat, and curing.

Leading Edge Protective Tapes

Similar to protective coatings and other physicochemical methods, the protective tapes to prevent blade erosion are designed and applied flexibly depending on the degree of blade erosion, resilience, and the performance operability of the turbine. In general, the process of applying leading edge tapes protection includes the following main steps:

-

- Prepare the surface to be implemented, clean and remove dirt.

- Apply the tapes to the preset position.

- Flatten shell, remove creases, wrinkles and air bubbles.

- Address the edge of the protective tape with adhesive and specialized solutions.

- Comprehensive surface inspection, reinforcement and caring.

>> Read more: Wind Turbine Blade Repair Services in Vietnam

Protection Solution for Wind Turbine Erosion (blades, nacelle covers and rotor hub) in Vietnam

Besides the wind turbine blade, the nacelle covers and rotor hub are critical structural components that exposure directly with external hazards like precipitation, dust, UV radiation and lightning strikes. With the main function of protecting the turbine machinery including the generator, gearbox and control system components, nacelle covers and rotor hub must be regularly inspected and maintained to ensure delivery low weight, temperature resistance, non-corrosion and rigidity.

To attack those problems, MBWIND provide solutions for surface layer protection for wind turbine blades, nacelle covers and rotor hub, in any onshore and offshore wind farm across Vietnam. We apply the surface protection methods by coating or gelcoat to against harsh climates in Vietnam, as well as the local conditions that cause erosion and wear.

>> Read more: Nacelle & Hub Wind Turbine Repair Service in Vietnam

After 1 Year, What Solution Operators Should Need To Prevent Leading Edge Erosion?

As equipment operating in special conditions, wind turbine blades must be directly exposed to weather agents such as: sun ray, wind, rain, snow, lightning stroke, direct UV rays from the sun. Therefore, after certain period of time, specifically after about a year, investors must regularly inspect the performance condition of the turbine and fortify the protection measures for the leading edge protection as well as blade surface, especially with offshore wind farm projects.

With two options for protecting the turbine blade surface that MBWIND proposes, including protective coating and protective tapes for blade surface, investors can equip suitable types of specialized tape and gel coat for each reality erosion case.

As mentioned above, investors and operators should consider the properties of conductivity ability (heat and electrical), adhesion, resilience, toughness, high strength, aesthetics, and other physicochemical characteristics of these methods to reach the optimal solutions for leading edge protection.

MBWIND – The Prestigious Provider Solution for Leading Edge Protection in Vietnam

Profound understanding the concerns of investors and operators about leading edge erosion of wind turbine blades, MBWIND constantly advances techniques and sought for the most optimal solution to protect turbine blades from all erode factors; helping all wind power farms onshore and offshore throughout Vietnam can operate in the safest, most efficient and economical way.

Coming to us, no distress has existed yet, because we provide a robust and well-rounded service of leading edge protection solutions with the most thoughtful quality, from surveying the reality condition to after-sales maintenance consultancy.

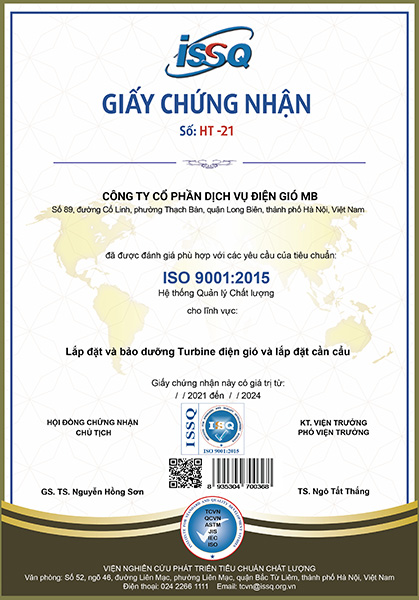

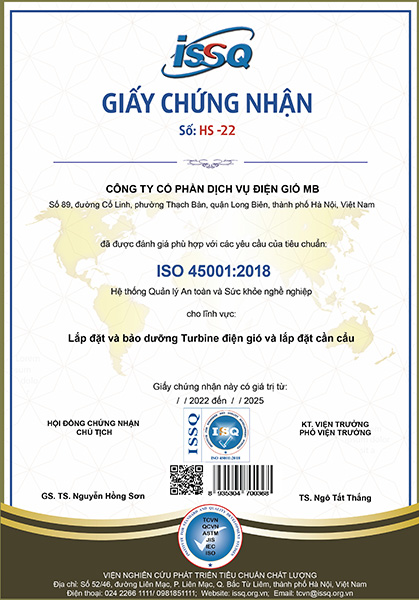

We are committed to bringing investors, as well as customers, the most impressive service experience with:

- Professional expertise, well-trained, bilingual technicians.

- Full equipment for construction such as: Crane, Forklift… Chemical substance.

- Service quality meets international standards, complete package, attentive and dedicated.

- Contracts and policies are comprehensive and transparent.

- Reasonable prices go along with quality, ensuring cost optimization.

- Using the working platform to ensure safety and high performance.

- Ready to serve and give advice 24/7. We delight in support all time.

CONTACT FOR SUPPORT

We are always delighted to receive your question, feedback, and any suggestions you might raise about Leading Edge Protection Solutions in Vietnam.

MBWIND staff are available 24 hours a day, 7 days a week by customer desk, live chat & by phone for those times when you need help.

For more information or any enquires please get in touch with us via email: info@mbwind.com.vn or call us for immediate assistance at (+84) 904 629 636.

MBWIND is honored to serve and support you!

+84 904 629 636 GET BEST QUOTE